Intelligent conveying equipment system

The intelligent conveying equipment system is the application of automatic control technology, information technology and advanced manufacturing technology to realize the timing, constant speed, and fixed-point conveying of materials and workpieces between specified positions, and control them to complete lifting, swinging, tilting, and flipping at preset spatial positions. A complete logistics system for actions. The application of intelligent conveying equipment system greatly improves the efficiency of production logistics, reduces production energy consumption, and makes the production and manufacturing process more intelligent and flexible.

The main products and services of the intelligent conveying equipment system include skid conveying system, plate chain conveying system, ground drag chain conveying system, friction conveying system, roller conveying system, single-track bicycle trolley conveyor system, double-track bicycle trolley conveyor system, skateboard conveyor system , reverse monorail conveying system and painting (drying) double chain conveying system, etc. The specific product uses and schematic diagrams are as follows:

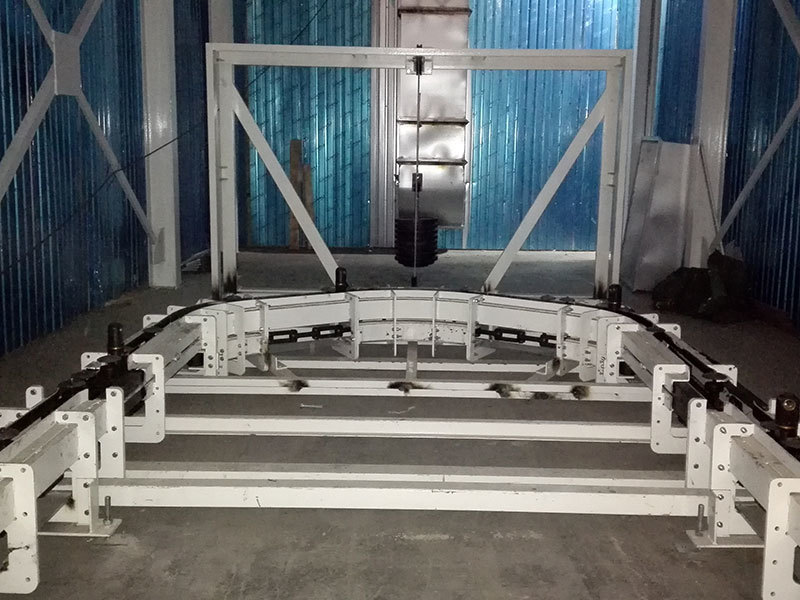

Skid Conveyor System

It is used to complete the transportation and storage of workpieces such as automobile bodies and parts in the production and circulation process of welding, painting, and final assembly.

Plate chain conveyor system

It is mainly used as interior assembly line, final assembly line, adjustment line, rainwater conveying line, final inspection line, etc. in automobile assembly workshop.

Ground drag chain conveyor system

It is mainly used for the final assembly of automobiles, construction machinery, agricultural equipment, etc., and the final assembly of axles and other components.

Friction conveying system

Mainly divided into ground friction line and air friction line, which are generally used in WBS (welded body storage) storage area, PBS (painted body storage) storage area, paint line run-off, empty trolley storage, final assembly door line, Body storage and other areas.

Roller conveyor system

It is mainly used in the production process of product transportation, storage area classification and storage.

Monorail Bicycle Trolley Conveying System

Mainly used in automobile coating pretreatment, electrophoresis conveyor line, final assembly conveyor line, door line, interior line, chassis line, etc.

Double Track Bicycle Trolley Conveying System

It is mostly used in electrophoresis conveyor lines for pre-coating of heavy-duty, ultra-long and ultra-wide workpieces such as buses and commercial vehicles, as well as final assembly conveyor lines.

Skateboard Conveyor System

Mainly used in automobile interior assembly line, final vehicle assembly line, combined assembly of engine and gearbox, etc.

IMC Conveyor System

It is mainly used for workpiece conveying in the coating and drying furnace system.

Painting (drying) double chain conveyor system

It is mainly used in the conveying of painting and drying process sections in automobile coating production.

CASE SHOW

Chassis line

Cab bike line

Interior skateboard line

Instrument line

Door conveyor line

Chassis air friction line

Interior skateboard line

Adjustment Plate Chain Line

服务领域

Service area

地址

山东省潍坊市诸城舜泰街1398号

传真

0536-6015555